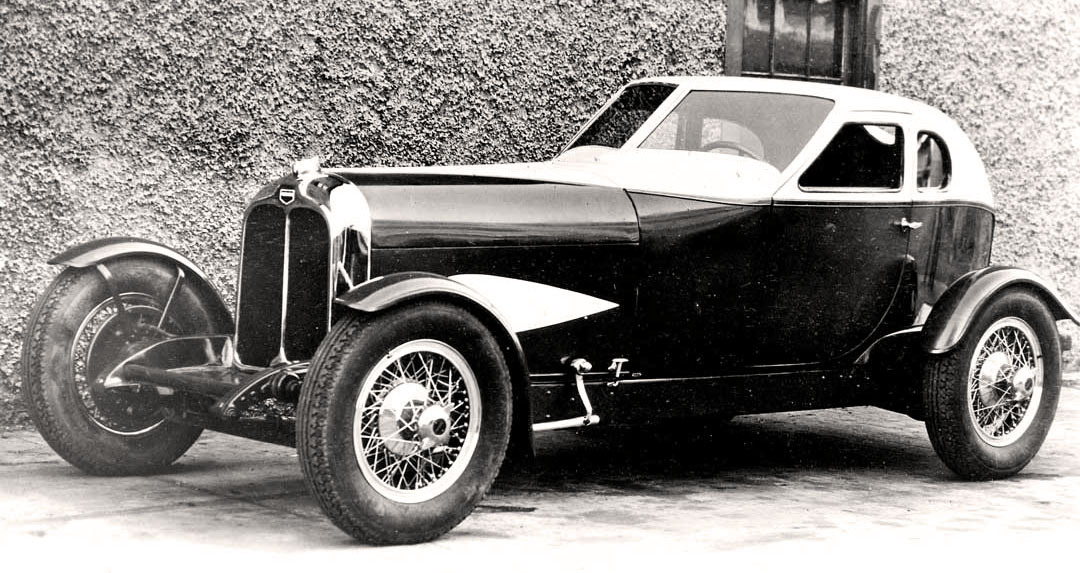

1916 Pierce-Arrow 38-C-4 Convertible/Coupe

- Story Cars

.png/v1/fill/w_320,h_320/file.jpg)

- Mar 21, 2024

- 1 min read

The 1916 Pierce-Arrow 38-C-4 Convertible/Coupe stands as a testament to the pioneering use of aluminum in car production by Pierce-Arrow Motor Car Company. While aluminum had been utilized in automobiles since the early days, it was often limited to top-of-the-line models due to its expense and the challenges associated with working with it.

Pierce-Arrow broke new ground by employing cast aluminum body technology, utilizing cold rivets to unite cast aluminum panels and create the complete body structure. Although the process itself was relatively simple, perfecting the technology took years of refinement.

The cast aluminum bodies produced by Pierce-Arrow in the early twentieth century represented a significant advancement in aluminum casting technology in terms of both size and quality. These bodies were renowned for their strength, silence, and durability, setting a new standard for automotive construction.

However, despite their exceptional qualities, the tremendous cost associated with the hand labor required to create, assemble, and finish these bodies proved to be unsustainable for Pierce-Arrow, particularly in the postwar market of the 1920s. Even for a manufacturer of high-end automobiles where cost was not a primary concern, the economic challenges of the era ultimately led to a shift away from cast aluminum bodies.